Laser rangefinder sensor's detection effect is not affected by the surface condition of the workpiece, and laser distance sensors has almost no limitation on the surface color or state of the object, making it effective in detecting a variety of types of objects.

Our laser range finder can also detect through gaps or holes in objects, making it suitable for a wide range of applications, including automated measurement in industrial production, distance control in construction, and robot navigation, among others.

-

01.

01.**High-precision measurement**: It can provide measurement results with an accuracy of up to millimeters or even smaller units, ensuring the accuracy of the data.

-

02.

02.**Independent of Color and Material**: The device can accurately measure distances of objects of various colors, textures, and materials, without being affected by their inherent characteristics. For example, it can provide precise data when measuring black rubber and white metal.

-

03.

03.**Wide Sensing Range**: It has a broad measurement range from short distances to long distances, meeting the needs of different application scenarios. For example, it can easily measure distances ranging from a few centimeters to several hundred meters.

-

04.

04.**Fast Response**: It can complete the measurement quickly and provide the results promptly, improving work efficiency.

-

05.

05.**Good Stability and Reliability**: It can maintain stable performance under different environmental conditions, such as temperature changes and humidity differences, and work reliably for a long time.

-

06.

06.**Low Power Consumption**: It is energy-efficient and reduces usage costs and dependence on energy.

-

07.

07.**Compact and Lightweight**: It is easy to install and carry, adapting to various installation locations and mobile application scenarios.

-

08.

08.**Strong Resistance to Interference**: It can effectively counteract the influence of external electromagnetic interference and other factors to ensure the accuracy of the measurement.

-

09.

09.**Easy to Integrate and Operate**: It can be conveniently integrated with other devices and systems, and the operation interface is simple and easy to understand.

-

1

1 -

2

2 -

3

3 -

4

4 -

5

5

-

01.

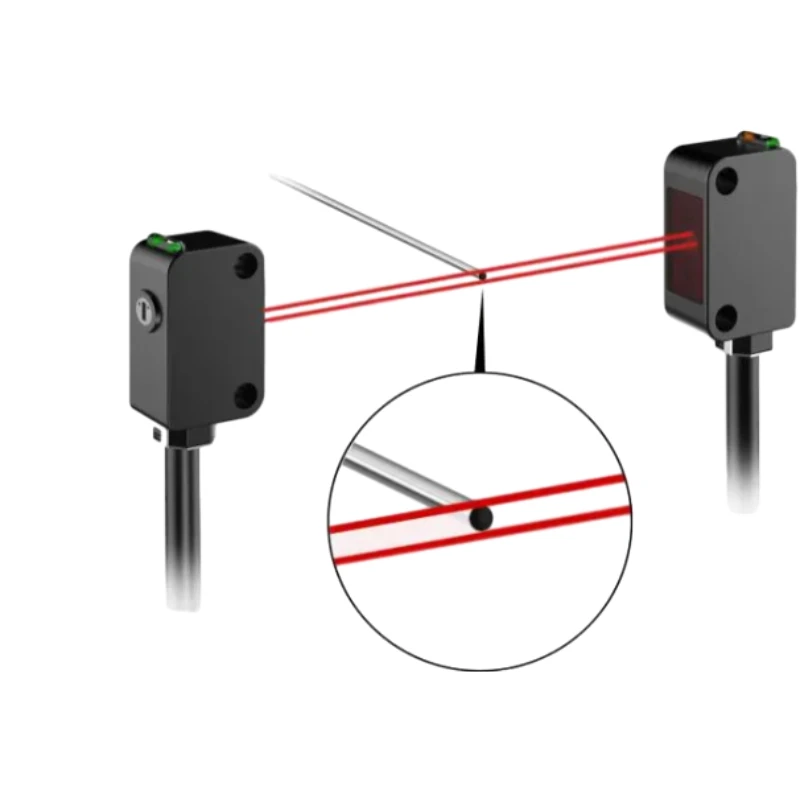

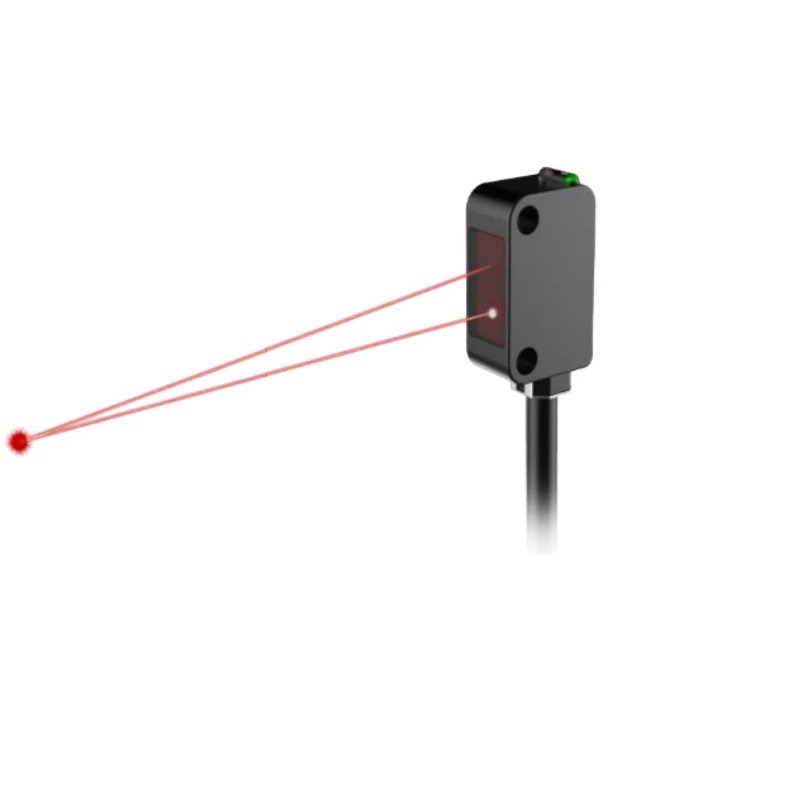

01.In cases where objects need to be detected as they pass through a production line, laser distance sensors are often used, either through-beam or reflective. A through-beam laser distance sensor consists of an emitter and a receiver, which are installed on opposite sides of the production line. The emitter continuously emits a laser, and the receiver receives the laser. When no object passes through, the receiver can receive the laser signal normally. When an object passes through, the laser will be blocked by the object, and the receiver will not receive the signal, thus judging that an object has passed through. A reflective laser distance sensor, on the other hand, installs the emitter and receiver on the same side, and it emits a laser towards the object and receives the reflected laser. The distance or position of the object can be calculated by measuring the time difference or phase difference between the emitted and received laser.

-

02.

02.For example, in some automated production lines, reflective laser distance sensors are used to detect objects on a conveyor belt. The sensor is installed at an appropriate position above the conveyor belt, so that the laser beam can cover the area where objects pass through. When a product passes through, the sensor can accurately measure the distance or position of the object and transmit the signal to the control system to achieve counting, positioning, or other related operations. At the same time, appropriate parameters and algorithms are set to ensure that workers operating nearby will not be misidentified. This not only improves production efficiency but also ensures the accuracy and reliability of inspection, while avoiding interference to workers.

-

03.

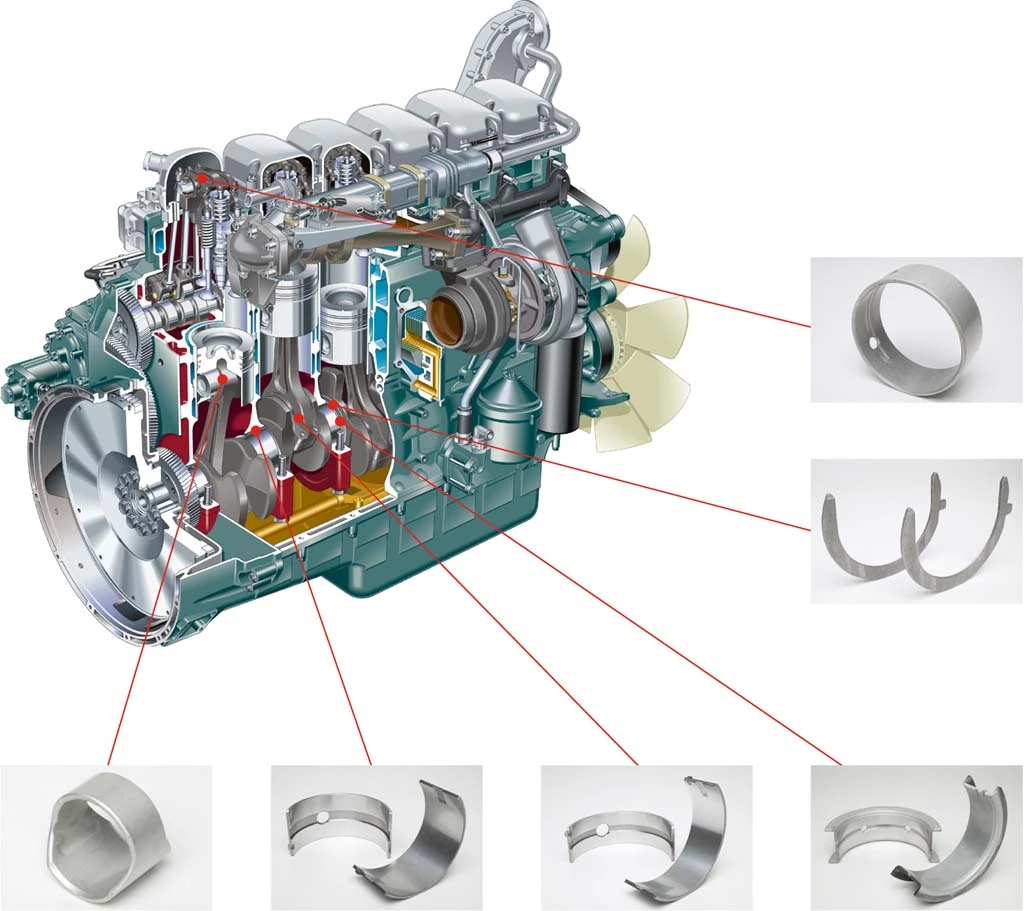

03.In large warehouses, laser rangefinder sensors are used to determine the location of goods on shelves in order to achieve efficient inventory management and automated retrieval. The sensors are installed on the top or side of the shelves, and when goods are stored or retrieved, the sensors can precisely measure the distance between the goods and the sensors, thus accurately obtaining the location information of the goods. In this way, the warehouse management system can have real-time access to the location of goods, improving the efficiency and accuracy of warehousing operations.

-

04.

04.For example, an e-commerce warehouse uses this technology. When new goods are received, the laser rangefinder sensor quickly detects the location of the goods and transmits the data to the system, allowing workers to quickly locate the goods for outbound operations, greatly reducing the time spent searching for goods.

-

The Principle Behind Laser Distance Measurement

-

Laser distance measurement is a precise and efficient technique used to determine the distance between a sensor and a target object. It relies on laser technology and advanced optical principles, commonly using time-of-flight, phase shift, or triangulation methods to achieve high accuracy and reliability across various applications.

The time-of-flight method is one of the most prevalent principles. In this approach, a laser emits a pulse of light that travels to the target and reflects back to the sensor. The system measures the time it takes for the light to complete its journey, and using the speed of light as a constant, it calculates the exact distance. This method is particularly effective for measuring long distances, making it ideal for applications like surveying, construction, and logistics.

The phase shift method, on the other hand, involves modulating the laser beam's intensity or wavelength. The sensor compares the phase of the emitted light to the phase of the reflected light. The difference between these phases provides the distance measurement. This principle is often used for applications requiring high precision over shorter ranges, such as in manufacturing or quality control.

The triangulation method is commonly employed for close-range measurements. A laser beam is projected onto the target, and the reflected light is captured by a detector. The position of the reflected laser spot on the detector shifts depending on the distance, enabling the system to calculate precise measurements using geometric triangulation.

-

Laser Distance Sensors: Precision and Versatility in Measurement

-

Laser distance sensors are cutting-edge devices that provide precise, non-contact measurements of distance by utilizing laser technology. These sensors operate by emitting a laser beam towards a target object, which reflects the light back to the sensor. By analyzing the reflected light, the sensor calculates the distance between itself and the target, offering high accuracy and speed.

One of the key advantages of laser distance sensors is their ability to measure over long distances with minimal error, making them ideal for applications such as industrial automation, construction, and surveying. They offer a wide range of measurement capabilities, from a few millimeters to several kilometers, depending on the sensor type and intended use. This flexibility makes laser distance sensors suitable for a variety of tasks, including material positioning, alignment, and distance monitoring in dynamic environments.

In addition to their long-range capability, laser distance sensors are highly reliable and can perform in challenging conditions, such as extreme temperatures, dust, and vibrations. This makes them valuable in industries like mining, agriculture, and logistics, where environmental factors can often interfere with traditional measurement tools. The non-contact nature of laser sensors also ensures that they do not damage delicate or sensitive materials during measurement.

Modern laser distance sensors often feature digital outputs and are easily integrated into automated systems, providing real-time data for controlling machinery or optimizing processes. They come in various forms, including handheld models for portable use and fixed models for continuous monitoring in industrial settings.

Q1:Are you trading company or manufacturer?

We are manufacturer.

Q2: Can we be your distributor?

We are looking for distributor and agent all over the world.

Q3: How's the package?

Normally are cartons, but also we can pack it according to your requirements.

Q4: How's the delivery time?

lt depends on the quantity you need, 1-25 days usually

Q5: How accurate are Laser Range Finders?

A: Laser Range Finders generally offer high accuracy, with many models capable of measuring distances with an error margin of just a few millimeters or centimeters. However, the accuracy can be affected by factors such as the reflective surface of the target, the angle of incidence, and atmospheric conditions. Always check the specifications of the specific model you are considering to understand its accuracy capabilities.

Q6: Can Laser Range Finders be used in bright sunlight?

A: Yes, Laser Range Finders can typically be used in bright sunlight, although the intense light may make it more difficult to see the display or aim the device accurately. Some models may have special features, such as polarized lenses or sun shades, to help reduce glare and improve visibility. Always test the device in the conditions you plan to use it in to ensure it performs as expected.

Q7: How far can a Laser Range Finder measure?

A: The maximum measuring distance of a Laser Range Finder depends on the specific model and its design. Some models can measure distances of just a few meters, while others can measure up to several kilometers. Always check the specifications of the device to understand its maximum range and ensure it meets your needs.

Q8: Can Laser Range Finders be used to measure curved surfaces?

A: Laser Range Finders are generally designed to measure the distance to a single point on a surface. If you need to measure a curved surface, you may need to take multiple measurements at different points and use a method such as triangulation or fitting a curve to the data points to estimate the overall shape and dimensions.

Q9: How do I ensure the Laser Range Finder is calibrated correctly?

A: Ensuring that your Laser Range Finder is calibrated correctly is important for accurate measurements. Many models come with calibration instructions or tools, and it is important to follow these carefully. If you are unsure how to calibrate your device, you may need to consult the manufacturer's support or a professional service.

Q10: Can Laser Range Finders be used in rainy or snowy conditions?

A: The use of Laser Range Finders in rainy or snowy conditions can be challenging, as water and snow can absorb or scatter the laser beam, reducing its effectiveness. Additionally, moisture can damage the electronics and optics of the device. Always check the specifications and warnings of your specific model to understand its environmental limitations and take appropriate precautions, such as using a waterproof case or avoiding use in extreme weather conditions.

Q11: How do I choose the right Laser Range Finder for my needs?

A: Choosing the right Laser Range Finder depends on several factors, including the specific application, the required accuracy and range, the size and weight of the device, and the budget. It is important to research different models and their capabilities, as well as consider the level of support and training available from the manufacturer. Additionally, users may want to consider features such as ease of use, battery life, and compatibility with other devices or software.

Q12:How does a Laser Range Finder work?

A Laser Range Finder works by emitting a very narrow, focused beam of light towards the target object. The light reflects off the object and returns to the device. The time taken for the light to travel to the object and back is measured, and since the speed of light is known, the distance can be calculated using the formula: distance = (time x speed of light) / 2.

Q13:What are the common uses of a Laser Range Finder?

Laser Range Finders are used in a variety of applications including surveying, hunting, golfing, forestry, and in the construction industry. They are also used in robotics for navigation and obstacle avoidance, and in the military for targeting and mapping.

Q14:What are the advantages of using a Laser Range Finder over traditional measuring tools?

Laser Range Finders offer several advantages over traditional measuring tools such as tape measures or rulers. They are faster, more accurate, and can measure distances to objects that are hard to reach or in hazardous locations. They also reduce human error and are less time-consuming.

Q15:Can a Laser Range Finder be used in any weather conditions?

Most Laser Range Finders are designed to be weather-resistant and can be used in various conditions. However, heavy rain, snow, or fog can affect the accuracy of the measurements. It's important to check the specifications of the device to ensure it meets your requirements for environmental conditions.

Q16:How do I choose the right Laser Range Finder for my needs?

When choosing a Laser Range Finder, consider the maximum range you need, the accuracy required, the environmental conditions it will be used in, and any additional features such as a built-in camera, compass, or inclinometer. Also, ensure that the device is user-friendly and fits within your budget.

Q17:Are Laser Range Finders safe to use?

Yes, Laser Range Finders are generally safe to use. They emit very low power laser beams that are not harmful to the eyes or skin. However, it is always recommended to follow the manufacturer's safety instructions and avoid pointing the laser at reflective surfaces or directly into people's eyes.

Q18:How do I maintain my Laser Range Finder?

To maintain your Laser Range Finder, keep it clean and dry. Avoid dropping it or exposing it to extreme temperatures. Regularly check the battery life and replace it as needed. It's also important to store the device in a safe place when not in use to prevent damage.

Q19:Can a Laser Range Finder be calibrated?

Yes, most Laser Range Finders come with a calibration feature that allows the user to adjust the device for accuracy. Calibration should be done periodically, especially if the device is used frequently or in harsh conditions. Refer to the user manual for specific calibration instructions.

Q20:What is the typical battery life of a Laser Range Finder?

The battery life of a Laser Range Finder can vary depending on the model and usage. On average, most devices can last anywhere from 4 to 10 hours of continuous use. Some models may offer longer battery life or have power-saving features that extend the battery life. Always check the product specifications for the expected battery life.