The advantages of PLC application in flour mill equipment and the services we can provide are as follows:

Solution for High Initial Investment Cost: The hardware equipment, software programming, installation, and commissioning of the PLC control system all require certain costs. For some small flour processing enterprises or enterprises with limited funds, the initial investment cost may be relatively high. We can provide products and services with higher cost performance. At the same time, we can provide PLC customization for some equipment, allowing customers to achieve automation in the production links that need it most with the least cost. For example, for automatic packaging, we can provide customers with flour extraction rate data, which helps to increase the extraction rate of fine flour and directly improve customer profits.

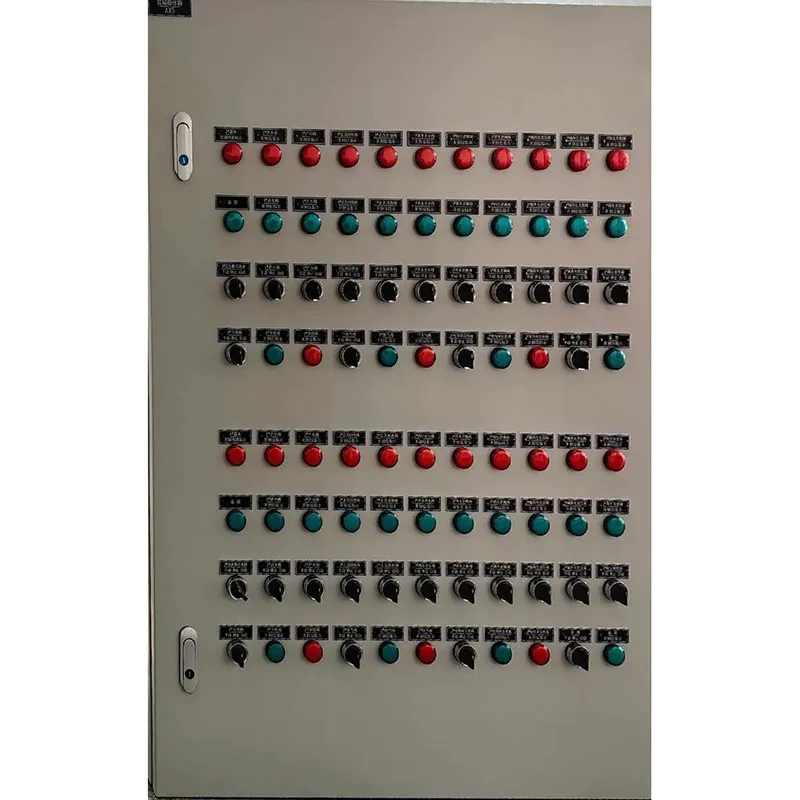

Improvement for High Environmental Requirements of PLC: Although the PLC itself has a certain anti-interference ability, the flour processing workshop usually has harsh environmental conditions such as dust, humidity, and temperature. If the protective measures are not appropriate, it may affect the normal operation of the PLC system, reduce the reliability and service life of the system, and even lead to equipment failure. For the PLC in the flour mill, through solutions such as optimizing the control cabinet layout, installing a sealed control cabinet, setting up an air filtration device, selecting a dust-proof PLC, and installing heat dissipation and temperature control equipment, the stability and reliability of the PLC in the harsh environment of the flour processing workshop can be significantly improved, its service life can be extended, and the normal automated operation of the flour mill equipment can be ensured.

High-level Programming and Maintenance Team: We have professional programmers to write, debug, and maintain the PLC program and provide comprehensive after-sales service. We also cooperate with enterprises to train relevant operators to fully utilize the functions of the PLC system and handle failures in a timely manner.

Comprehensive After-sales Service: Since the PLC control system involves multiple aspects such as hardware, software, and communication, when a failure occurs, it may be relatively complex to troubleshoot the cause and location of the failure. Our after-sales team has mature technical experience and professional equipment and can quickly troubleshoot and repair without affecting the production progress.

Professional Service: When the flour mill equipment is upgraded or integrated with other systems, there may be compatibility issues between the PLC system and new equipment and new software, requiring additional debugging and modification work. We will provide the most professional upgrade and modification solutions to reduce the maintenance cost and upgrade difficulty of the system.